Material-minimized extrusion of carbon-reinforced concrete (CRC) | Funding Period 2

During the first funding period, progress was made in the development of methods for extruding thin, formable, high-performance carbon-reinforced concrete (CRC) structures with variable cross sections while minimizing material usage. Furthermore, initial advancements in the exploration of concrete slab structures using assembled CRC components were made. In funding period 2, the focus of D02 will shift:

- from the use of solid cross sections to hollow-core cross sections,

- from the use of flat carbon reinforcements (CRs) to continuous reinforcement concepts with shaped carbon reinforcements,

- from the large CO2 footprint of pure ordinary Portland cement (OPC) concrete mixtures to low-clinker cements with the possibility of CO2 uptake, and

- from single CRC elements to assembled extruded components.

The research proposal focuses on developing high performance, lightweight, formwork-free, and resource-efficient extruded carbon-reinforced concrete (ExCRC) components with minimized material usage and low embodied CO2. The research has four primary objectives:

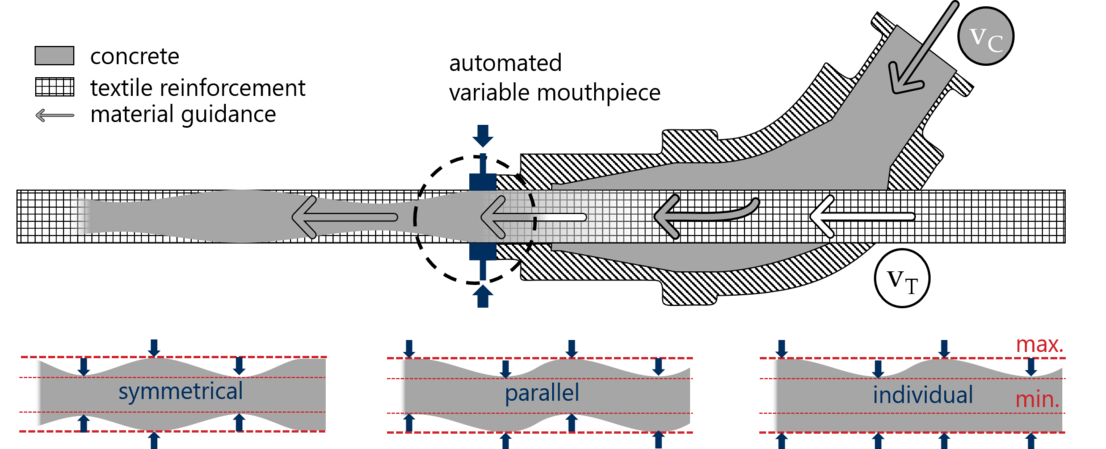

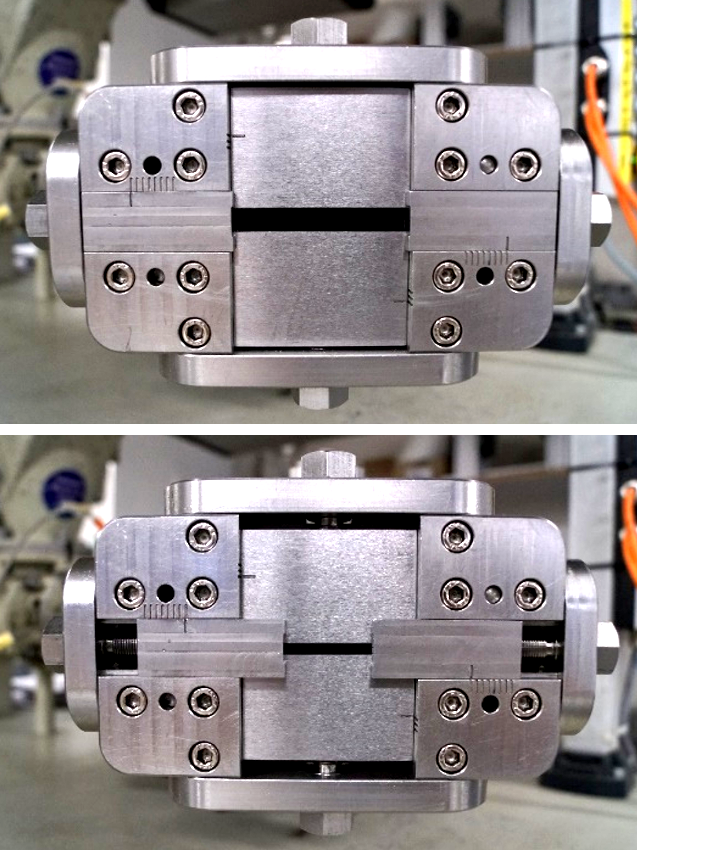

- Development of a method for extruding hollow-core profiles using shaped textiles. To achieve this, precise geometric dimensioning and proper feeding of the shaped CR must be ensured.

- Development of a scalable predictive simulation model that combines underlying physical-chemical processes with the required engineering properties to enable flawless extrusion beyond lab scale.

- Use of concrete mixtures with a 50% lower CO2 footprint compared to OPC mixtures, and of CO2-curing strategies as a curing method to effectively reduce the environmental impact, while maintaining OPC-like hardening behavior.

- Assembly and connection of various ExCRC elements to modular load-bearing structures.

Scientists

![Prof. Dr.-Ing. Thomas Matschei [Translate to English:] Thomas Matschei](/fileadmin/_processed_/d/1/csm_2024_D02_Matschei_b2ae8c156b.jpg)

D-52062 Aachen (Germany)

D- 52062 Aachen (Germany)

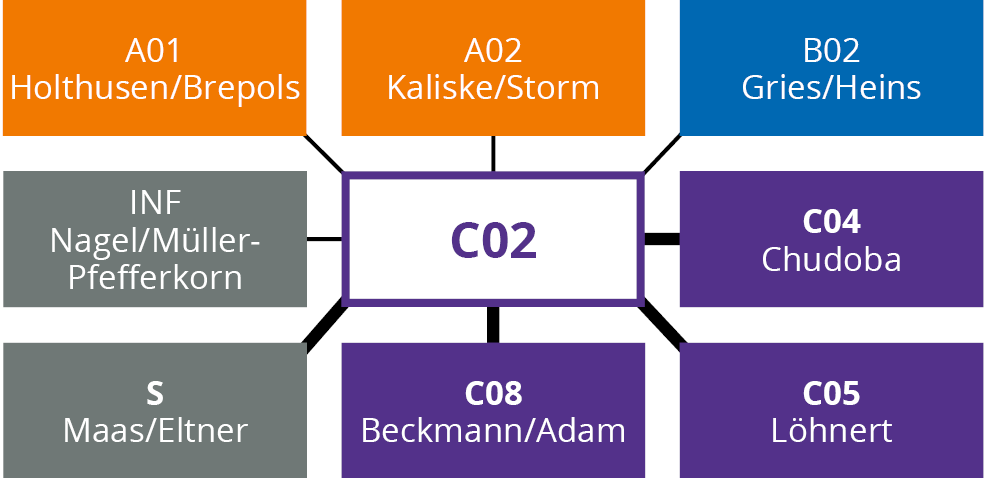

Cooperations

Ehemalige | Former involved

Prof. Dr.-Ing. Michael Raupach (Teilprojektleiter, RWTH Aachen, 07/2020 – 06/2024)

Dr.-Ing. Matthias Kalthoff (Wissenschaftlicher Mitarbeiter, RWTH Aachen, 06/2020 – 0/2023)

Jabkob Beckers (Wissenschaftlicher Mitarbeiter, RWTH Aachen)

Principles for the Extrusion of Carbon-Reinforced Concrete Structures | Funding Period 1

The aim of project D02 is the investigation of a material-saving and economic production process for thin, carbon-reinforced concreete structures with variable cross sections, which are characterized by simple to strongly curved and complex geometries. Therefore the continuous production with an extruder and a subsequent forming of these structures is focused. Extrusion has the technological and economic potential to produce complex components with high precision and quality without time-consuming and cost-intensive formwork and reinforcement processes.

Not only does rapid production significantly increase cost-effectiveness, it also counteracts the scarcity of raw materials through waste minimization and material-saving component geometries. The integration of technical textiles made of carbon fibers in the extrusion process further increases the load-bearing capacity of the component.

Within the framework of D02, the seed fund project "Targeted CO2 impact of extruded concrete components" (1st round 2022) is carried out.

Publikationen | Publications

Backes, J. G. M.; Scheurer, M.; Kalthoff, M.; Gries, M.; Matschei, T.; Raupach, M.; Traverso, M. (2022) Sustainability of textile reinforcements for carbon concrete – today and tomorrow in: Stokkeland, S.; Braarud, H. C. [eds.] Concrete Innovation for Sustainability – Proc. for the 6th fib International Congress 2022, 12.–16.06.2022 in Oslo (Norway), Oslo: Novus Press, p. 2130–2138.

Beckers, J.; Kalthoff, M.; Morales Cruz, C.; Matschei, T. (2023) Possibilities of extrusion production in concrete construction in: Claßen, M.; Hegger, J.; Matschei, T.; Raupach, M. [eds.] Beiträge zur 10. DAfStb-Jahrestagung mit 62. Forschungskolloquium, 26./27.09.2023 in Aachen, p. 161–171 – DOI: 10.18154/RWTH-2023-08021

Bosbach, S.; Kalthoff, M.; Morales Cruz, C.; Adam, V.; Matschei, T.; Classen, M. (2023) Digital Prefabrication of Lightweight Building Elements for Circular Economy: Material-Minimised Ribbed Floor Slabs Made of Extruded Carbon Reinforced Concrete (ExCRC) in: Buildings 13, issue 12, 2928 – DOI: 10.3390/buildings13122928

Dhahir, M. K.; Kalthoff, M.; Neef, T.; Friese, D.; Beckmann, B.; Cherif, Ch. Matschei, T.; Mechtcherine, V.; Marx, S. (2023) Developing the Chemical Prestressing Technology for Textile Carbon Reinforced Concrete in: Ilki, A.; Çavunt, D.; Çavunt, Y. S. [eds.] Building for the Future: Durable, Sustainable, Resilient – Proc. of fib Symposium 2023, 05.–07.06.2023 in Istanbul (Turkey), publ. in: Lecture Notes in Civil Engineering 350, Cham: Springer, p. 1428–1438 – DOI: 10.1007/978-3-031-32511-3_146

Kalthoff, M.; Bosbach, S.; Backes, J.; Morales Cruz, C.; Traverso, M.; Claßen, M.; Raupach, M.; Matschei, T. (2023) Fabrication of lightweight, carbon textile reinforced concrete components with internally nested lattice structure using 2-layer extrusion by LabMorTex in: Construction and Building Materials 395, 132334 – DOI: 10.1016/j.conbuildmat.2023.132334

Kalthoff, M.; Bosbach, S.; Matschei, T.; Raupach, M.; Claßen, M.; Hegger, J.(2022) Investigations on material-minimized slabs made of extruded carbon reinforced concrete in: Stokkeland, S.; Braarud, H. C. [eds.] Concrete Innovation for Sustainability – Proc. for the 6th fib International Congress 2022, 12.–16.06.2022 in Oslo (Norway), Oslo: Novus Press, p. 1047–1057.

Kalthoff, M.; Nebel, H.; Morales Cruz, C.; Schmidt, L.; Weniger, A.; Backes, J. G.; Traverso, M.; Raupach, M.; Matschei, T. (2023) CO2 Curing for Extruded Textile Reinforced Concrete Components – Requirements and Potentials in: Ilki, A.; Çavunt, D.; Çavunt, Y. S. [eds.] Building for the Future: Durable, Sustainable, Resilient – Proc. of fib Symposium 2023, 05.–07.06.2023 in Istanbul (Turkey), publ. in: Lecture Notes in Civil Engineering 349, Cham: Springer, p. 1265–1274– DOI: 10.1007/978-3-031-32519-9_128

Kalthoff, M.; Raupach, M.; Matschei, T. (2022) Extrusion and Subsequent Transformation of Textile-Reinforced Mortar Components—Requirements on the Textile, Mortar and Process Parameters with a Laboratory Mortar Extruder (LabMorTex) in: Buildings 12, 726 – DOI: 10.3390/buildings12060726

Kalthoff, M.; Raupach, M.; Matschei, T. (2022) Investigation of Rheological Test Methods for the Suitability of Mortars for Manufacturing of Textile-Reinforced Concrete Using a Laboratory Mortar Extruder (LabMorTex) in: Constr. Mater. 2, p. 217–233 – DOI: 10.3390/constrmater2040015

Kalthoff, M.; Raupach, M.; Matschei, T. (2022) Investigation into the Integration of Impregnated Glass and Carbon Textiles in a Laboratory Mortar Extruder (LabMorTex) in Materials 14, 7406, p. 217–233 – DOI: 10.3390/ma14237406

Kalthoff, M.; Raupach, M.; Matschei, T. (2022) Materialminimiertes Bauen mit extrudiertem Textilbeton in: Beton 72, issue 6, p. 195–198.

Kruppa, H.; Kalthoff, M.; Neef, T.; Reißig, S.; Mechtcherine, V.; Raupach, M.; Matschei, T.; Vollpracht, A. (2023) Alkali-Activated Binder Requirements for Extrusion and 3Dd-Printing of Carbon Reinforced Concrete in: Ilki, A.; Çavunt, D.; Çavunt, Y. S. [eds.] Building for the Future: Durable, Sustainable, Resilient – Proc. of fib Symposium 2023, 05.–07.06.2023 in Istanbul (Turkey), publ. in: Lecture Notes in Civil Engineering 349, Cham: Springer, p. 1275–1283 – DOI: 10.1007/978-3-031-32519-9_129

Morales Cruz, C., Bosbach, S., Kalthoff, M., Beckmann, B., Matschei, T. and Classen, M. (2024), Materialminimierte Rippen- und Wabendecken aus extrudierten Carbonbetonstegen. Beton- und Stahlbetonbau, 119: 873-881. https://doi.org/10.1002/best.202400069

Neef, T.; Kalthoff, M.; Müller, S.; Backes, J. G.; Raupach, M.; Matschei, T.; Traverso, M.; Mechtcherine, V. (2023) Extrusion of High Yield Strength Carbon Reinforced Concrete with Mineral Impregnated Rovings in: Ilki, A.; Çavunt, D.; Çavunt, Y. S. [eds.] Building for the Future: Durable, Sustainable, Resilient – Proc. of fib Symposium 2023, 05.–07.06.2023 in Istanbul (Turkey), publ. in: Lecture Notes in Civil Engineering 350, Cham: Springer, p. 1568–1576 – DOI: 10.1007/978-3-031-32511-3_160

Neef, T.; Kalthoff, M.; Müller, S.; Morales Cruz, S.; Raupach, M.; Matschei, T.; Mechtcherine, M. (2025) Mineral-impregnated carbon fibers reinforcement for concrete elements manufactured by extrusion, Cement and Concrete Composites, Volume 157, https://doi.org/10.1016/j.cemconcomp.2024.105909

Scheurer, M.; Dittel, G.; Kalthoff, M.; Raupach, M.; Matschei, T.; Gries, T. (2023) Evaluation of Properties of Impregnated Reinforcement Textiles Cured Within Concrete for Applications in Concrete Extrusion in: Ilki, A.; Çavunt, D.; Çavunt, Y. S. [eds.] Building for the Future: Durable, Sustainable, Resilient – Proc. of fib Symposium 2023, 05.–07.06.2023 in Istanbul (Turkey), publ. in: Lecture Notes in Civil Engineering 349, Cham: Springer, p. 1293–1302 – DOI: 10.1007/978-3-031-32519-9_131

Scheurer, M.; Kalthoff, M.; Matschei, T.; Raupach, M.; Gries, T. (2022) Analysis of Curing and Mechanical Performance of Pre-Impregnated Carbon Fibers Cured within Concrete in: Textiles 2, issue 4, p. 657–672 – DOI: 10.3390/textiles2040038

Unger, R.; Kalthoff, M.; Müller-Pfefferkorn, R.; Nagel, W. (2022) Managing research data in civil engineering research projects in: Stokkeland, S.; Braarud, H. C. [eds.] Concrete Innovation for Sustainability – Proc. for the 6th fib International Congress 2022, 12.–16.06.2022 in Oslo (Norway), Oslo: Novus Press, p. 2668–2675.

Dissertation | Doctoral thesis

Matthias Kalthoff:Extruded Thin-walled Textile Reinforced Concrete Components with Flexible Shape [Doktorarbeit | doctoral thesis]. RWTH Aachen, Datum der mündlichen Prüfung | Date of oral examination: 25.05.2023, publiziert | published: 2023, https://publications.rwth-aachen.de/record/960721/files/960721.pdf | DOI: 10.18154/RWTH-2023-06358

Studentische Arbeiten | Student's works

Fromm, N. (2023)Experimentelle Untersuchungen zum Einsatz von multipel getränkten Carbontextilien im Extrusionsprozess [Institutspraktikum | institute's internship] (mit | with B03)

Gümüskaya, B. (2022) Experimentelle und numerische Untersuchungen zur Herstellung von extrudierten carbonbewehrten aufgelösten Deckenelementen [Masterarbeit | Master's thesis] (mit | with C02)

Hartig, C. (2021) Experimentelle Analyse der Aushärtung und Verbundeigenschaften vorimprägnierter Carbonfasern in Beton [Masterarbeit | Master's thesis] (mit | with B02)

Lube, A. (2023) Experimentelle Untersuchungen zur Vorspannung von extrudierten Carbonbetonbauteilen [Bachelorarbeit | Bachelor's thesis]

Marbach, J. M. (2023) Gezielte CO2-Beaufschlagung von extrudierten Bauteilen [Institutspraktikum | institute's internship]

Marbach, J. M. (2023) Experimentelle Untersuchungen zum Einsatz von multipel getränkten Carbontextilien im Extrusionsprozess [Bachelorarbeit | Bachelor's thesis] (mit | with B03)

Müllerschön, P. (2022) Untersuchung zur Aushärtung von Tränkungen vorimprägnierter Carbonfasern im Beton für den Extrusionsprozess [Masterarbeit | Master's thesis] (mit | with B02)

Nguyen, T. L. (2022) Anforderungen an Geometrie und Formgebung bei Textilbetonelementen [Bachelorarbeit | Bachelor's thesis] (mit | with B02)

Sabusch, C. (2023)Experimentelle Untersuchungen zur Entlüftung und Verdichtung von Betonen im Extrusionsprozess [Bachelorarbeit | Bachelor's thesis]

Beckers, J. (2024) Extruded carbon-reinforced concrete elements as concrete shear connectors for the production of dissolved sandwich elements [Masterarbeit | Master's thesis]

Weiss, G. (2024) Selbstheilung von extrudierten, textilbewehrten Carbonbeton durch den Zusatz des Enzyms Carbonanhydrase [Bachelorarbeit | Bachelor's thesis]