Sonderforschungsbereich/Transregio 280

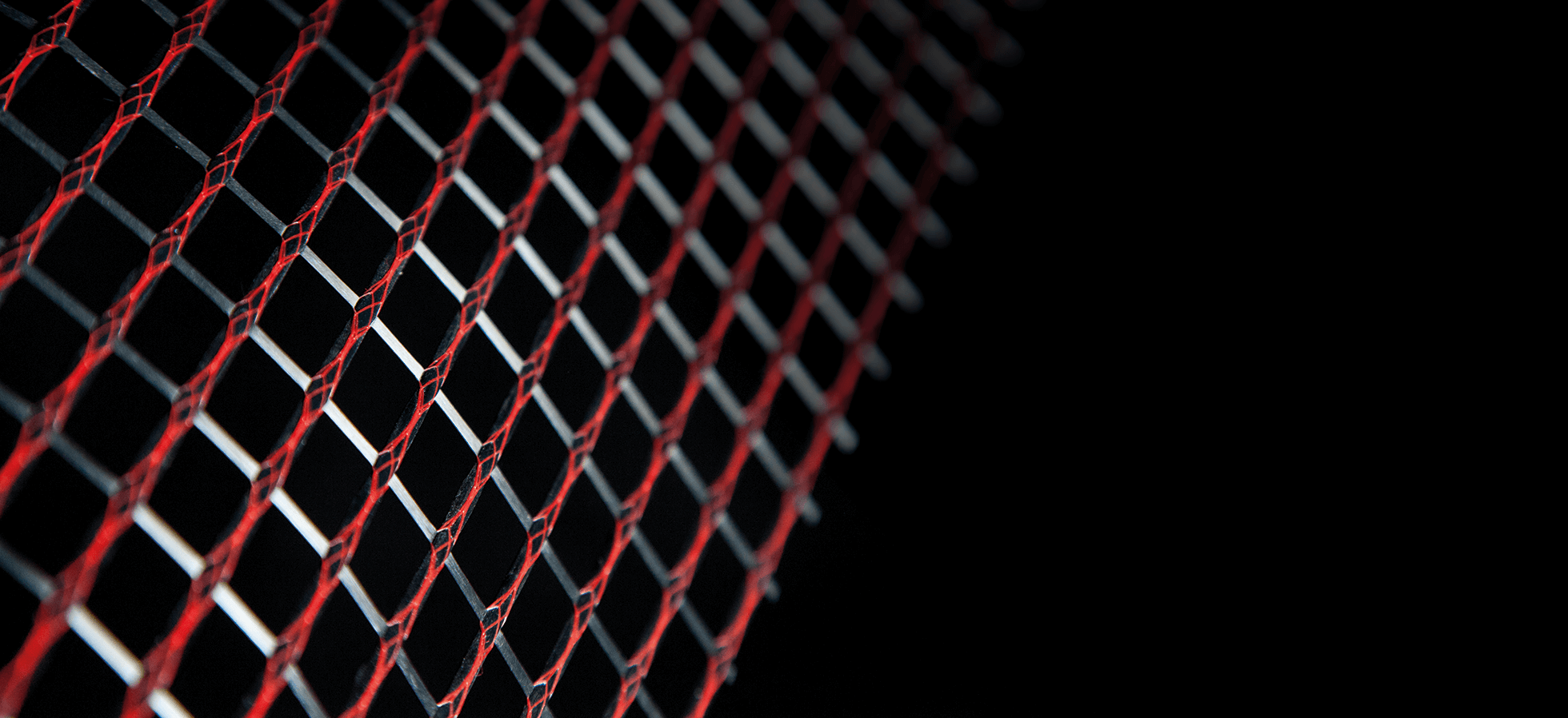

Konstruktionsstrategien für materialminimierte Carbonbetonstrukturen – Grundlagen für eine neue Art zu bauen

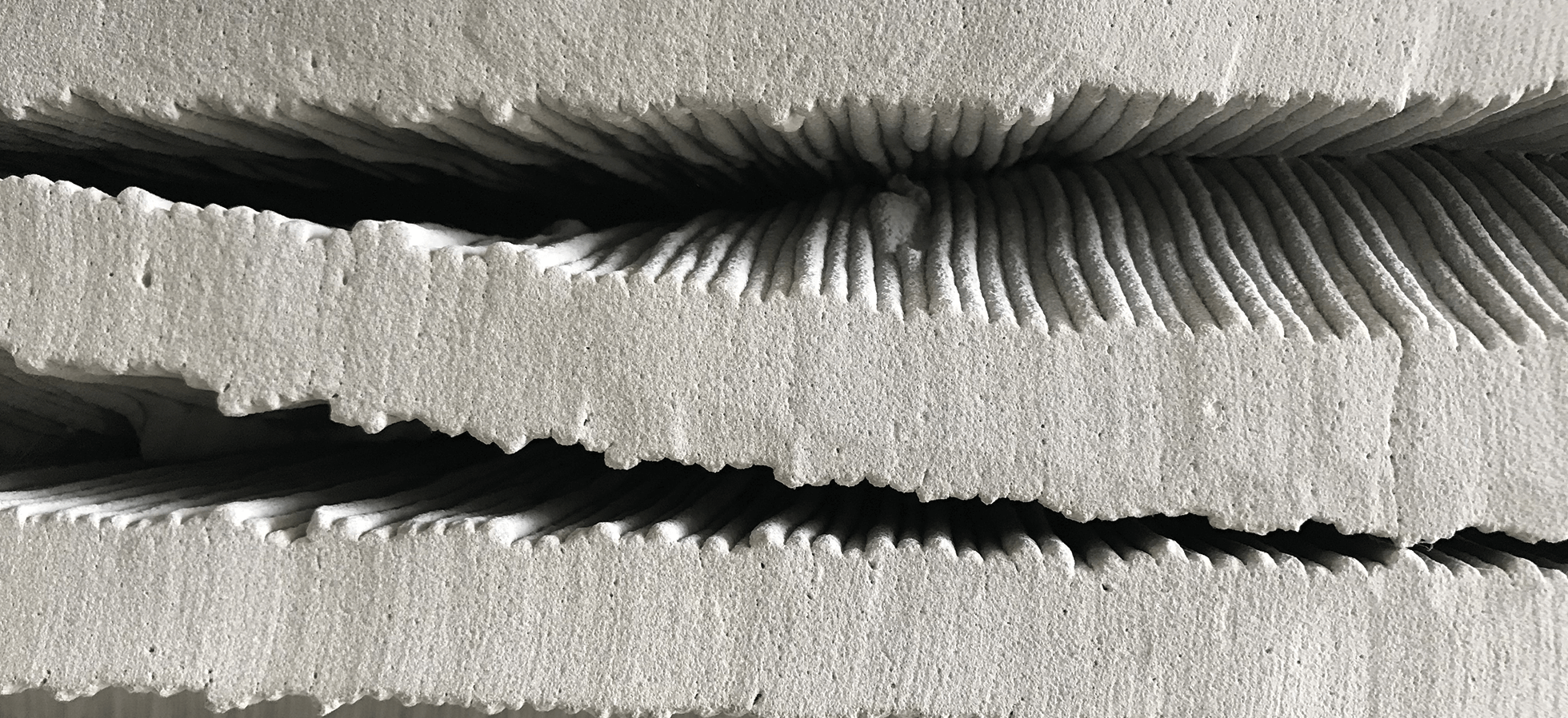

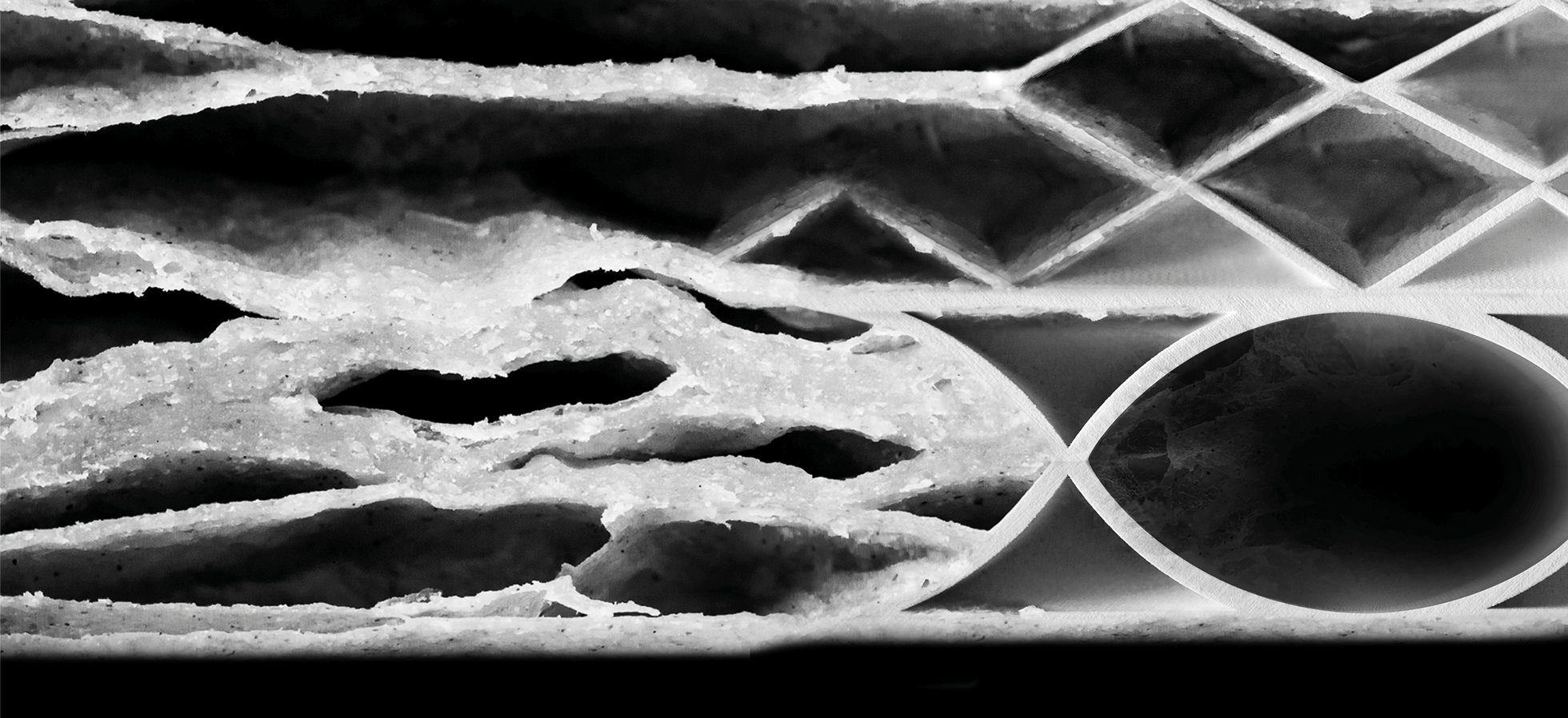

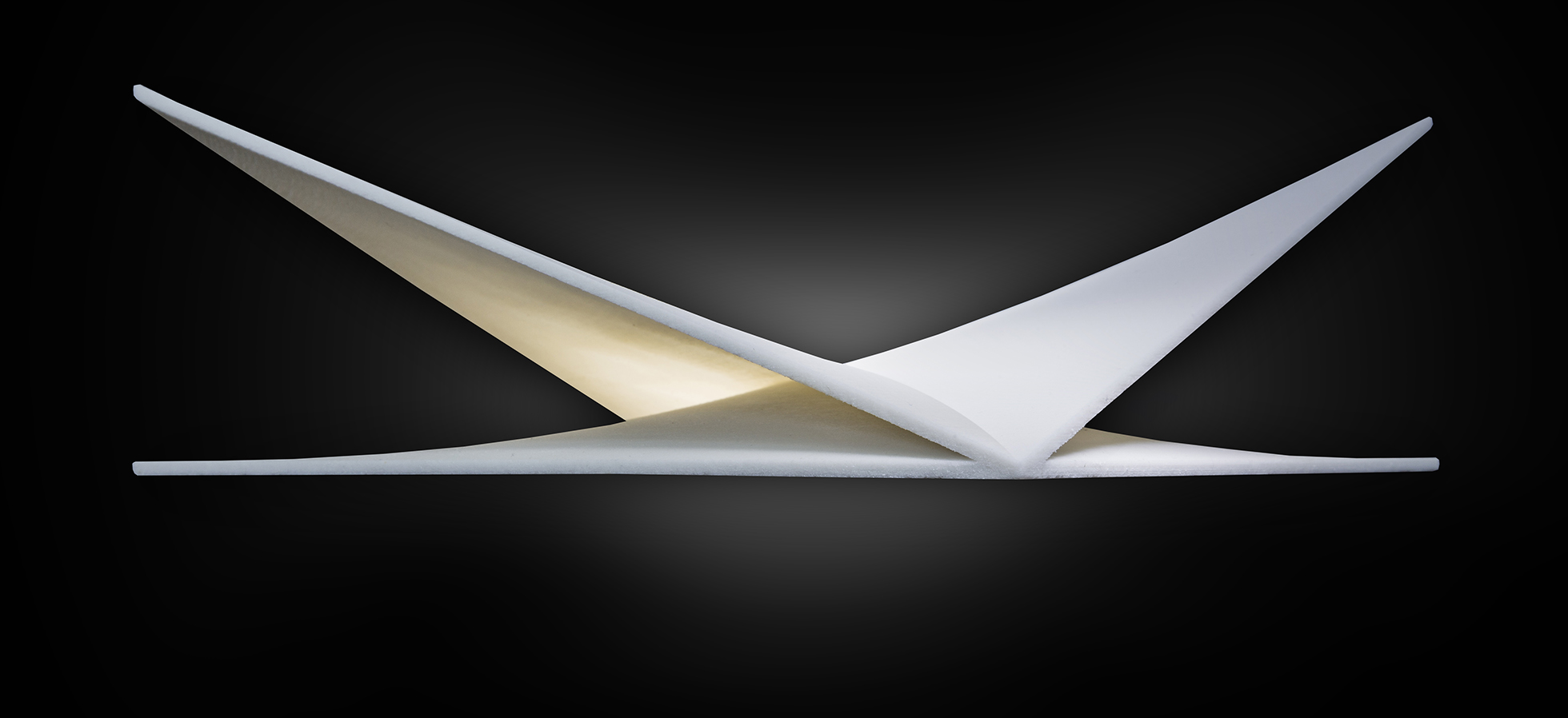

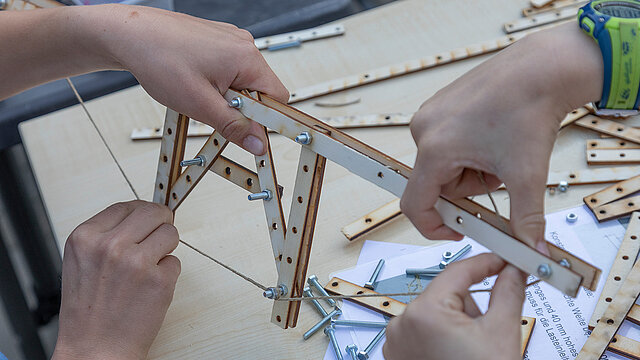

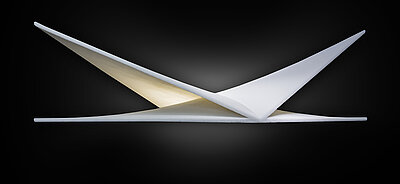

Das Ziel des SFB/TRR 280 ist es, neue Grundlagen für das Bauen der Zukunft zu schaffen. Die Strategieentwicklung des SFB/TRR 280 ist darauf ausgerichtet, innovative Konzepte und intelligente Konstruktionen aus Carbonbeton zu entwickeln. Geeignete Methoden für den Entwurf, wie die Modellierung und die Konstruktion mit neuen Materialien erfordern daher eine tiefergehende Grundlagenforschung. Zentraler Ideengeber für die Bauelementengeometrie sind die Biologie, vorrangig die Botanik, aber auch die Fachbereiche Mathematik und Kunst. Angestrebt werden Konstruktionsformen aus mineralischen Kompositen, die Kräfte überwiegend durch Normalspannung abtragen und mit neuen industriellen maschinengestützten Fertigungsmethoden hergestellt werden.

Die Entwicklung neuartiger Strukturen ist verbunden mit Fragen der Herstellbarkeit, der produktbezogenen Nachhaltigkeitsbewertung und der Weiterentwicklung des Verbundwerkstoffs selbst. Neue und innovative Konstruktionsstrategien ermöglichen eine völlig andere Formensprache, reduzieren den Ressourcen- und Energieverbrauch und gewährleisten gleichzeitig eine hohe Gebrauchstauglichkeit, Tragsicherheit und Langlebigkeit.

Die etwa 50 Forscherinnen und Forscher an der Technischen Universität Dresden, der RWTH Aachen University, am Leibniz-Institut für Polymerforschung Dresden e.V. und am Botanischen Garten Hamburg bündeln exzellente Kompetenzen. Ziel ist, eine international sichtbare Vorreiterrolle in der Erforschung des materialminimierten Bauens mit kohlefaserverstärkten mineralisch-basierten Werkstoffen einzunehmen.

Die Deutsche Forschungsgemeinschaft DFG fördert den Sonderforschungsbereich/Transregio 280 seit Juli 2020.