Biomimetic, highly branched 3D textile reinforcement structures based on self-supporting technology approach | Funding Period 2

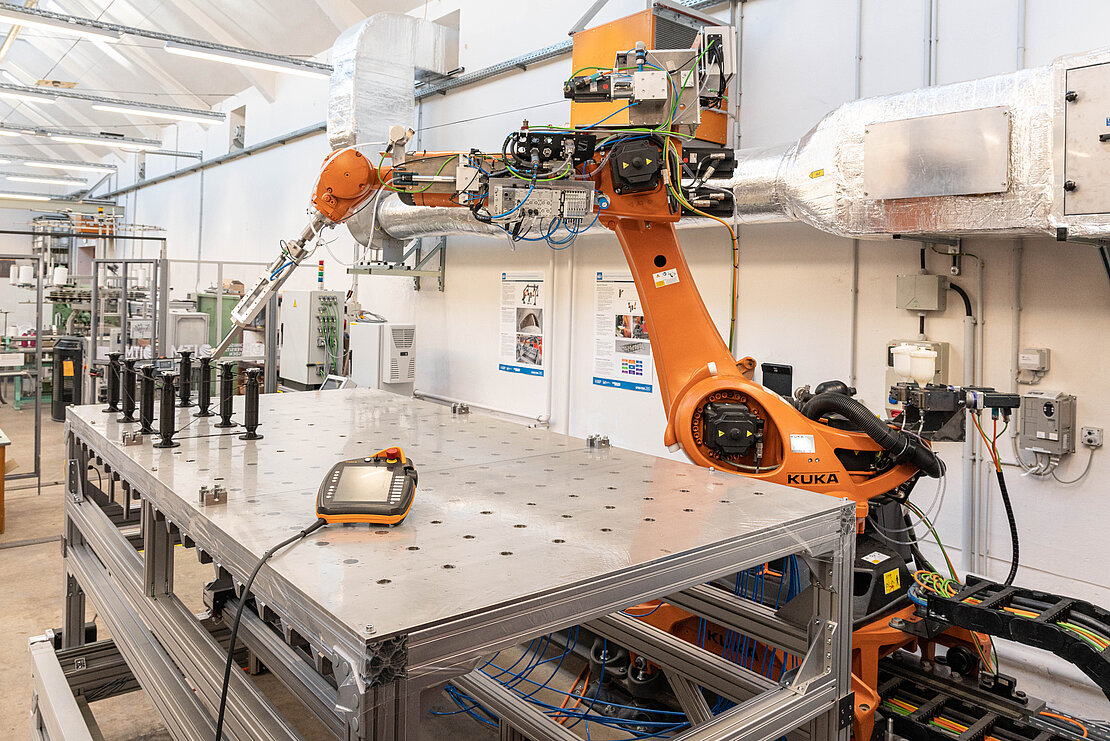

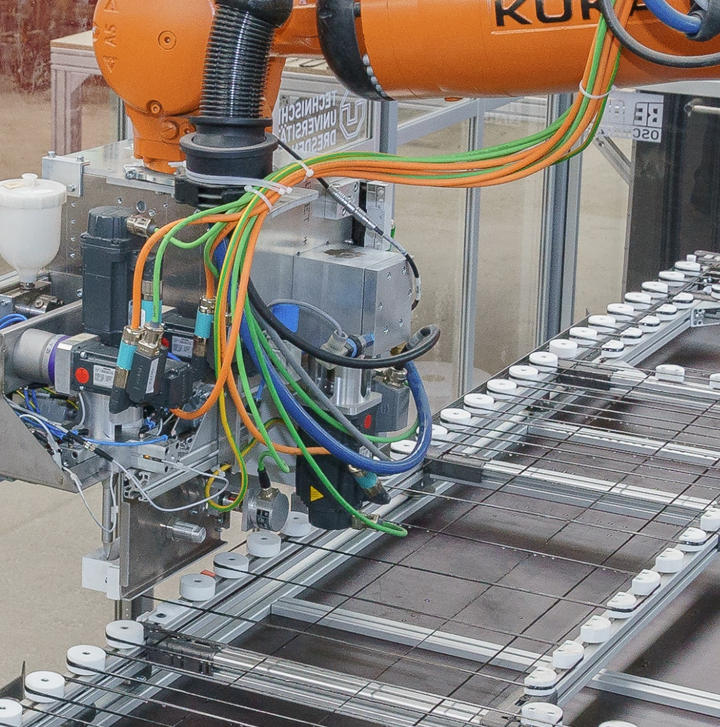

The goal of project B01 in funding period 2 is to mimic biological or alternatively inspired load transfer mechanisms in a much more differentiated way than currently possible. This will lead to a significant increase in the material efficiency of existing civil engineering structures and enable the development of entirely new design strategies. As a result, the reinforcement structure should be shaped with increased complexity, considering internally resolved structures. This requires a novel manufacturing technology for geometrically free, undamaged, distortion-free, and load-path–compatible yarn deposition in space for the realization of self-supporting 3D textile reinforcements. The key to these approaches is the development of a new methodology based on a cooperative robotic system.

A methodology for trajectories will be developed to effectively manage the movements of cooperating robots. Artificial intelligence will enable continuous monitoring of yarn deposition. The multi-branched reinforcement structures with load-path-adapted fiber orientation should be able to be installed, for example, in nodal areas between columns and beam or of sheets, and shells.

Scientists

D-01062 Dresden (Germany)

01062 Dresden (Germany)

01062 Dresden (Germany)

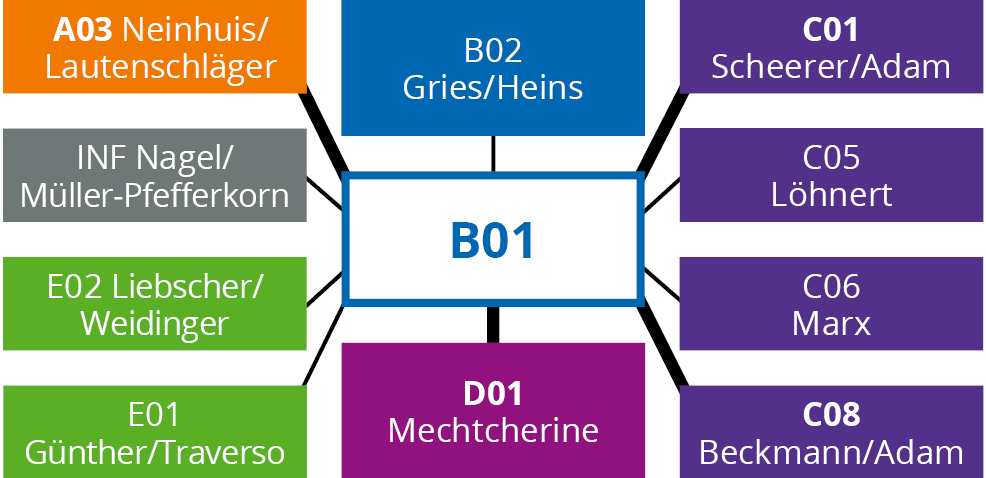

Cooperations

Ehemalige | Former involved

Danny Friese (research associate, TU Dresden, 07/2020 – 06/2024)

Biologically Inspired Load-Adapted 3D Textile Reinforcement Structures | Funding Period 1

Project B01 thematically focuses on the design and modeling of load-adapted and profiled textile reinforcement structures with spatial branched topologies based on sophisticated development principles from the botanical evolution. Therefore, the scientific findings supposed to be used to elaborate modularly built and tool-independent technological concepts as well as to realize and validate the robot-supported manufacturing facility. The objective of this research project concentrates on the realization of spatial branched 3D preform topologies for a resource-saving and material minimized carbon-reinforced concrete construction, where the textile and widely spread 3D reinforcement topologies are finally processed by a generative, concrete-based 3D printing technology.

Publikationen | Publications

Dhahir, M. K.; Kalthoff, M.; Neef, T.; Friese, D.; Beckmann, B.; Cherif, Ch. Matschei, T.; Mechtcherine, V.; Marx, S. (2023) Developing the Chemical Prestressing Technology for Textile Carbon Reinforced Concrete in: Ilki, A.; Çavunt, D.; Çavunt, Y. S. [eds.] Building for the Future: Durable, Sustainable, Resilient – Proc. of fib Symposium 2023, 05.–07.06.2023 in Istanbul (Turkey), publ. in: Lecture Notes in Civil Engineering 350, Cham: Springer, p. 1428–1438 – DOI: 10.1007/978-3-031-32511-3_146

Friese, D. (2021) Biologie und Robotik am Bau – Biologisch inspirierte lastangepasste 3D-Textilbewehrungsstrukturen | Biology and robotics in construction – Biologically inspired load-adapted 3D textile reinforcement structures in: CU reports, 2, p. 26/27.

Friese, D.; Cherif, Ch. (2021) Biologically inspired load adapted 3D textile reinforcement structures in: TRENDGUIDE Technical Textiles 64, issue 2, p. E117.

Friese, D.; Hahn, L.; Cherif, Ch. (2021) Biologically inspired load adapted 3D Textile Reinforcement Structures in: Material Science Forum 1063, p. 101–110 – DOI: 10.4028/p-8oa718[Langfassung des Vortrags von Friese, D. bei AUTEX 2021 – 20th World Textile Conference, 05.–09.09.2021 in Guimarães (Portugal, online), p. 187/188 (book of abstracts)].

Friese, D.; Hahn, L.; Cherif, Ch. (2023) Development of a yarn guiding and impregnation technology for robot-assisted fiber manufacturing of 3D textile reinforcement structures in: Proc. of 11th International Conference on Fiber-Reinforced Polymer (FRP) Composites in Civil Engineering (CICE 2023), 23.–26.07.2023 in Rio de Janeiro (Brazil) – DOI: 10.5281/zenodo.8164096.

Friese, D.; Hahn, L.; Le Xuan, H.; Mersch, J.; Neef, T.; Mechtcherine, V.; Cherif, C. (2023) Robot-Assisted Manufacturing Technology for 3D Non-Metallic Reinforcement Structures in the Construction Applications in: Buildings 13, issue 11, 2748 – DOI:https://doi.org/10.3390/buildings13112748

Friese, D.; Rjosk, A.; Hahn, L.; Lautenschläger, Th.; Neinhuis, Chr.; Cherif, Ch. (2022) Development of an application-oriented Yarn Impregnation and Fixation Technology for the Robot-supported Manufacturing of Biologically Inspired Load Adapted 3D Textile Reinforcement Structures in: Stokkeland, S.; Braarud, H. C. [eds.] Concrete Innovation for Sustainability – Proc. for the 6th fib International Congress 2022, 12.–16.06.2022 in Oslo (Norway), Oslo: Novus Press, p. 715–725.

Friese, D.; Scheurer, M.; Hahn, L.; Gries, T.; Cherif, Ch. (2022) Textile reinforcement structures for concrete construction applications––a review in: Journal of Composite Materials 56, issue 26, p. 4041–4064 – DOI: 10.1177/00219983221127181

Hahn, L.; Zierold, K.; Golla, A.; Friese, D.; Rittner, S.; Cherif, Ch. (2023) 3D Textiles Based on Warp Knitted Fabrics: A Review in: Materials 16, issue 10, 3680 – DOI: 10.3390/ma16103680

Mersch, J.; Friese, D.; Le Xuan, H. (2025) Toward the Automation of the 3D Robotic Coreless Filament Winding Process for High‐Performance Composite Materials With Multiple Reinforcement Levels in: Applied Research 4, issue 1, e202400145 - DOI: 10.1002/appl.202400145

Scheurer, M.; Friese, D.; Heins, K.; Hahn, L.; Mersch, J.; Cherif, C.; Gries, T. (2024) Novel Textile Reinforcements for Advanced Concrete Production Methods in: Mechtcherine, V.; Signorini, C.; Junger, D. [eds.]: Transforming Construction: Advances in Fiber Reinforced Concrete – Proc. of XI RILEM-fib Int. Symp. on Fiber Reinforced Concrete (BEFIB 2024), 15.–18.09.2024 in Dresden, publ. in RILEM Bookseries, Vol. 54, Cham: Springer Nature Switzerland, p. 778–785 – https://doi.org/10.1007/978-3-031-70145-0_92

Scheurer, M.; Friese, D.; Penzel, P.; Dittel, G.; Bhat, S.; Overhage, V.; Hahn, L.; Heins, K.; Cherif, C.; Gries, T. (2023) Current and future trends in textiles for concrete construction applications in: Textile 3, issue 4, p. 408–437 – https://doi.org/10.3390/textiles3040025

Dissertation | Doctoral thesis

Danny Friese:Entwicklung einer robotergestützten Technologie zur Herstellung von biologisch inspirierten, lastangepassten 3D-Textilbewehrungsstrukturen [Doktorarbeit | doctoral thesis]. TU Dresden, Datum der mündlichen Prüfung | Date of oral examination: 13.06.2024, publiziert | published: 10.10.2024, TUDpress

Vorträge und Poster | Oral presentations and posters

Friese, D. (2024) Robotergestützte Technologie zur Herstellung biologisch inspirierter, lastangepasster 3D-Textilbewehrungsstrukturen oral presentation at: CU Bau Webseminar Wednesday, 24.04.2024 (online)

Friese, D.; Hahn, L.; Cherif, C. (2023) Biologisch inspirierte, belastungsangepasste 3D-Textilbewehrungsstrukturen oral presentation at: CU Innovation Day "Von der Natur inspiriert – Nachhaltiges Bauen mit Faserverbundwerkstoffen", 29.06.2023 (online)

Rjosk, A.; Ritzert, S.; Macek, D.; Friese, D.; Neef, T.; Mechtcherine, V.; Cherif, C.; Reese, S.; Neinhuis, C.; Lautenschläger, T. (2023) A new approach to construction: using peltate leaves as inspiration in the design of novel carbon fibre reinforced concrete building components oral presentation at: 10. Bionik-Kongress, 12./13.05.2023 in Bremen (Proc. in preparation)

Studentische Arbeiten | Student’s works

Ritter, L. (2021) Konstruktiv-technologische Entwicklung eines Konzeptes zur formwerkzeuglosen, geometriegetreuen Garnfixierung im Raum [Forschungspraktikum | Research internship]

Albiez, L. (2022) Experimentelle Identifikation von Prozesseinflussfaktoren bei der robotergestützten 3D-Garndirektablage sowie die Ableitung von festigkeitsoptimierenden Schemata für den Ablageprozess [Bachelorarbeit | Bachelor’s thesis]

Xie, J. (2023) Numerische Betrachtung von Faserkunststoffverbundstrukturen als Basis für die robotergestützte Herstellung von Bewehrungen für Betonbauteile [Forschungspraktikum | Research internship]

Yang, Z. (2023) Technologisch-konstruktive Entwicklung einer robotergeführten Inline-Garntränkungseinheit für die hochproduktive, robotergestützte 3D-Garndirektablage [Diplomarbeit | Diploma thesis]